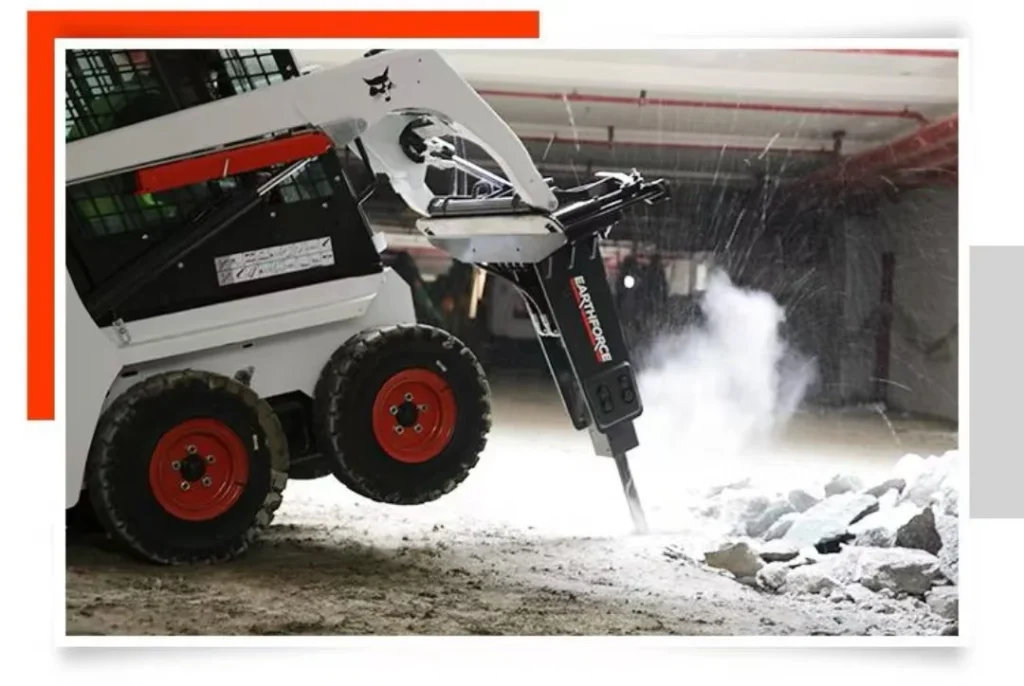

Are you overwhelmed by choices when shopping for a skid steer loader? Whether you’re a first-time buyer, brand-loyal operator, or looking to upgrade, this guide helps navigate your selection. Skid steers are versatile, but choosing the right one requires careful consideration of needs, budget, and long-term goals. Below are five key tips to make an informed decision—avoiding brand bias and overlooked specs for a smart purchase.

Here is Canary been working in the construction machinery industry for 10 years. Now, I will share with you how to quickly choose a suitable skid steer loader for yourself. I will also share with you some of my experiences.

1. Confirm Your Project Needs and Tasks

Before diving into specifications or brands, start by defining how you’ll use the skid steer. Skid steers are not one-size-fits-all; their design varies significantly based on tasks like ground-level work, material handling, or operating attachments.

1.1 Identify Primary Applications

- Ground-Level Tasks: If you’ll mainly be loading dirt, pushing snow, or sweeping surfaces, focus on models with efficient bucket capacities and maneuverability. For example, a small loader with a 0.15–0.35 m³ bucket might suffice for residential or light commercial jobs.

- Elevated Work: Tasks like unloading materials into trucks or reaching higher heights require a skid steer with adequate lift height and reach. Look for models with vertical lift arms, which offer more consistent height and reduced forward arc compared to radial lift designs.

- High-Flow Attachments: Tools like snow blowers, cold planers, or mulchers demand high-flow hydraulic systems (25–40 gpm). Standard flow systems (17–25 gpm) work for simpler attachments like augers or grapples.

1.2 Consider Job Site Logistics

- Terrain and Space: Narrow job sites (e.g., backyards or alleys) require compact dimensions—some models are as narrow as 36 inches. For rough terrain, tracked models offer better traction than wheeled ones, while wheeled versions excel on hard surfaces.

- Travel Distance: If you need to move between sites or cover long distances, prioritize models with higher travel speeds (up to 12 km/h) to save time.

2. Evaluate Key Performance Specifications

Once you understand your tasks, dive into the technical specs that determine a skid steer’s capability. These factors directly impact performance, efficiency, and compatibility with your workflow.

2.1 Load Capacity and Lift Height

- Load Capacity: Ranges from 600 lbs (ultra-compact models) to over 3,000 lbs (heavy-duty machines). Always choose a loader with a slightly higher capacity than your typical load (e.g., a 20% margin) to avoid overworking the engine and hydraulics.

- Lift Height: This determines how high you can dump materials. For truck unloading, aim for a lift height of at least 10 feet (3 meters). Vertical lift models often offer greater maximum height, while radial lift models excel in forward reach during mid-level lifts.

2.2 Hydraulic System and Attachments

- Flow and Pressure: As mentioned, high-flow hydraulics (25+ gpm) are essential for demanding attachments. Check the system’s safety pressure (e.g., 180 bar) to ensure it can handle heavy loads without overheating or leaking.

- Attachment Compatibility: Skid steers thrive on versatility, with attachments like forks, grapples, and grading blades. Ensure the loader’s quick-attach system is standard (e.g., ISO compatibility) to avoid proprietary restrictions.

2.3 Dimensions and Maneuverability

- Width and Height: Measure gateways, doorways, and work areas to ensure the loader fits. A 60-inch-wide model is common for residential use, while commercial sites may accommodate wider units.

- Turning Radius: Skid steers are known for zero-turn capability, but compact models navigate tighter spaces better than full-size ones.

2.4 Engine Type and Emissions

- Diesel vs. Gasoline: Diesel engines offer more torque and fuel efficiency for heavy duty work, while gas engines are lighter and suitable for lighter tasks.

- Emissions Standards: Newer models meet EPA Tier 4 or EU Stage V standards, which require advanced emissions systems (e.g., DPF, SCR). Older models (Tier 3 or lower) may be cheaper upfront but could face restrictions in regulated areas.

3. Balance Brand Reputation with Practical Support

While brand loyalty is natural, prioritizing suppliers support and reliability over logos will serve you better in the long run.

3.1 Look Beyond Colors and Logos

- Multiple Reliable Brands: Top manufacturers like Caterpillar, John Deere, Bobcat, and Kubota all produce high-quality skid steers, but lesser-known brands (e.g., Torchuck, JCB) may offer comparable specs at lower prices. Focus on proven reliability (e.g., customer’s feedback & after-service) rather than brand.

- Fleet Consistency: For fleet managers, sticking to one brand simplifies parts inventory, maintenance training, and software compatibility. Mixing brands can lead to higher costs and logistical headaches.

3.2 Consider Dealer Support

- Parts Availability: Ensure the dealer stocks common components (e.g., hydraulic hoses, filters) and offers fast shipping for rare parts. Delays in repairs can halt projects.

- Service Expertise: A dealer with trained technicians and quick response times is invaluable. Ask about warranty terms, routine maintenance packages, and emergency service options.

4. Prioritize Operator Comfort and Safety

A skid steer that’s uncomfortable or unsafe to operate will reduce productivity and increase fatigue.

4.1 Cab Features and Visibility

- Enclosed Cabs: For year-round use, opt for a cab with heating/air conditioning and dust filtration. Sliding or swing-open doors should offer easy entry/exit, and one-arm boom designs (on some models) improve side visibility.

- Ergonomic Controls: Look for intuitive joystick or hand-foot controls with adjustable seats. Some models offer electronic controls with customizable settings for new hand.

4.2 Safety Features

- ROPS/FOPS Compliance: All modern skid steers have Roll-Over Protective Structures (ROPS) and Falling Object Protective Structures (FOPS), but ensure the model meets current standards.

- Stability and Tipping Resistance: Check the machine’s operating weight and center of gravity. A lower center of gravity reduces tipping risks, especially on slopes.

4.3 Training and Support for New Operators

- Test Before You Buy: Rent a model to practice maneuvering, lifting, and using attachments. Pay attention to how easily you can see the bucket edges and navigate obstacles.

- Automatic Features: Some models offer self-leveling buckets or automatic boom positioning, which simplify tasks for novice operators.

5. Plan for Long-Term Maintenance and Costs

Buying a skid steer is an investment, so factor in lifetime costs beyond the sticker price.

5.1 Inspect Build Quality

- Frame and Boom Durability: Look for welded steel frames with minimal signs of wear (e.g., cracks, rust). Test the boom for smooth operation—jerky movements or sagging buckets may indicate hydraulic issues.

- Tire Types: Pneumatic tires are standard and cost-effective, but foam-filled or solid tires are better for harsh environments (e.g., debris, sharp rocks). Solid tires eliminate flat risks but are heavier and pricier.

5.2 Maintenance Requirements

- Hydraulic System Care: Leaking hoses or pumps are red flags. Regular fluid changes and filter replacements are critical to prevent system failures.

- Engine Maintenance: Diesel engines with emissions systems require more frequent filter changes (e.g., DPF cleaning). Older engines may be simpler but less efficient.

5.3 Resale Value and Longevity

- Depreciation Trends: Well-maintained brands like Bobcat or Caterpillar often hold value better, but any model’s resale price depends on usage history and upgrades.

- Warranty Coverage: Extended warranties (e.g., 5 years/5,000 hours) can protect against costly repairs in the first few years.

Conclusion: Make a Strategic Choice, Not a Branded One

Choosing a skid steer loader boils down to matching the machine to your tasks, budget, and support needs, not chasing a familiar logo. By focusing on specifications that align with your workflow, prioritizing dealer reliability, and planning for long-term maintenance, you’ll select a loader that delivers years of productivity. Remember: the best skid steer is the one that makes your job easier, safer, and more efficient—regardless of its paint color.

Ready to start your search? Use these tips to compare models objectively, and don’t hesitate to consult experts or rent before committing. Happy loading!